Worried about how your product looks in retail space? Concerned that your shipments may not be arriving safely?

Either way, the experts at BoldtSmith Packaging have experience working directly with product manufacturers and retailers to ensure consumer goods packaging is optimized properly. We’ll help you navigate complex packaging guidelines, and provide unique insights into projects that require cross-functional teams and data-backed results.

Whether you’re packaging and shipping household products, large furniture, small cosmetics or even food, CPG has its challenges.

There is a balance between eye-catching, functional design, sustainability, customer experience, materials and labor costs to keep margins intact. Our focus for the consumer packaging market is both increased revenue and cost savings.

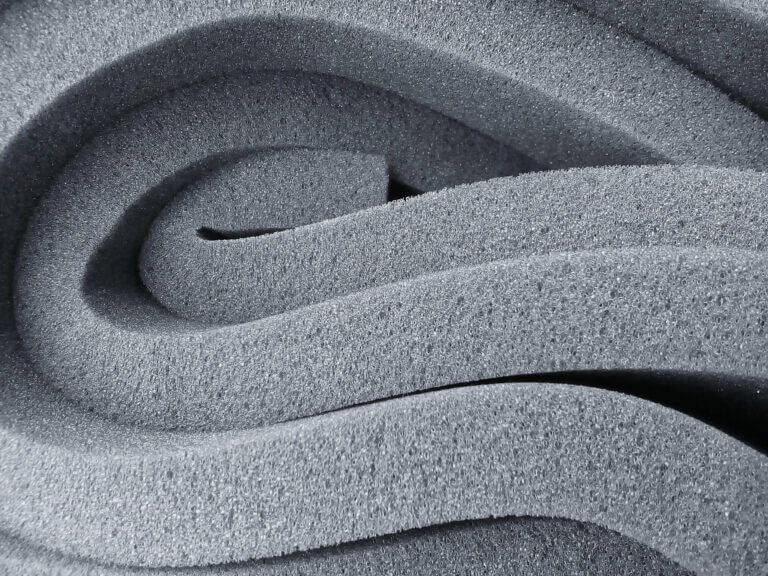

Cosmetics crushed, broken furniture, leaking cleaning products. Product damage is really brand damage. Working with BoldSmith Packaging, you can be confident in improved package quality and performance. We design and test to verify the product and packaging will survive the intended supply chain and various environmental conditions. Our data-based packing engineering and shipping optimization for damage reduction ensures that a wide variety of products will arrive just as intended.

CPG packaging projects often face tight, difficult-to-meet timelines. At BoldtSmith Packaging, we don’t just work Monday to Friday, 9-5. Our schedules are determined by our customers’ deadlines. In-house packaging engineers, expert designers and on-site sample-making capabilities play a key role in our packaging operations for quick turnarounds that aren’t possible at packaging manufacturers, many in-house departments, or with single designers who may have limited resources.

Loose products inside packaging can cause damage and greatly increase your shipping costs. Businesses need to fit more product into ocean containers when manufactured overseas while domestically manufactured products need to better fit on pallets. Optimizing how you ship your products from production efficiency to structural design means no wasted space or lost profits. Our custom packaging solutions help you stay on brand and optimized for cost.

Gone are the days when just switching to recyclable materials or reducing packaging waste was enough to qualify as sustainable packaging. Especially for CPG brands with weekly or monthly repeat purchases, true sustainability starts with optimized packaging design. We go beyond finding the right shipping supplies. We look at the entire supply chain to identify ways to streamline transit, increase the number of products per shipment, and properly protect products so there are no returns and exchanges for damage. That’s what we call NET GREEN™ and it’s how you implement successful and impactful sustainable packaging solutions.

CPG companies are required to follow proper labeling protocols that adhere to industry standards. But that shouldn’t interfere with packaging design and optimization. Our experts are hard-wired to respect labeling compliance.

Packaging and shipping isn’t just about corrugated boxes and paperboard or cans vs bottles. It requires a unique understanding of the product journey to ensure it’s problem-free.

We are data-driven engineers who make decisions for what’s best for your product, not the packaging materials. Learn why top name brands rely on BoldtSmith to provide optimized packaging specifications with elegant designs.

Interested in seeing more of the work at BoldtSmith? Explore case studies.

Make sure your product holds up and stands out.

1701 Pearl Street Suite 2

Waukesha, WI 53186

+1 262-203-9522

info@BoldtSmithPackaging.com

Want to keep up with our latest news and alerts? Sign up now and stay in the know.

Copyright © 2024 BoldtSmithPackaging.com