Case study

Industrial

Damage reduction

A leading swimming pool heat pump manufacturer was suffering damage to their pool heater due to their LTL (Less-Than-Truckload) shipping. They needed a package re-design to reduce damage, keeping in mind minimizing freight costs.

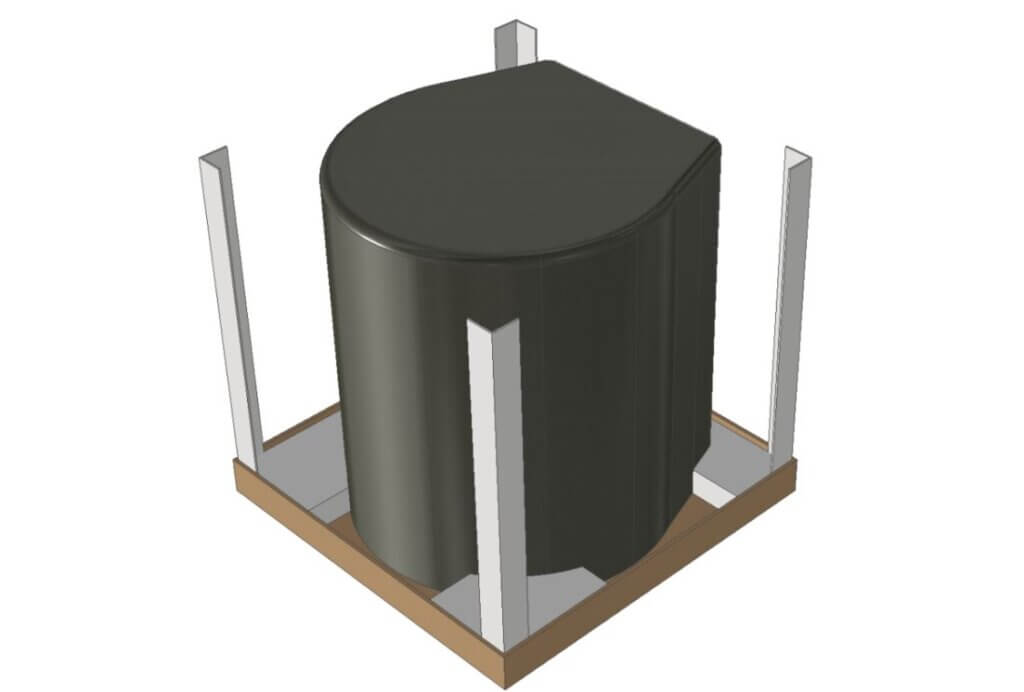

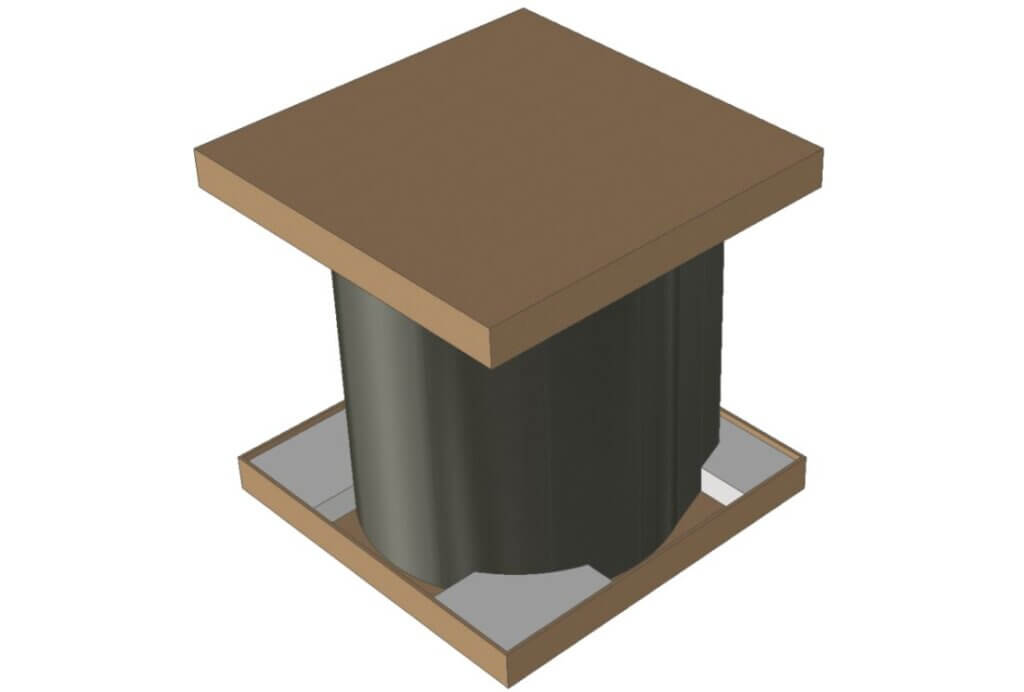

The BoldtSmith engineers developed 3D concepts laying out the pool heater’s dimensions within the packaging. From there, we designed 5 packaging solutions utilizing a variety of packaging materials including foam, molded pulp, corrugated, hexacomb and wood.

With different design options, the team ran through various samples to find the right material to withstand LTL shipping while staying within budget for their shipping and packaging needs.

After a final prototype was developed, we tested the packaging through rigorous ISTA standards alongside a financial analysis to determine if the packaging was safe for shipping while keeping the companies freight costs at a minimum.

By partnering with BoldtSmith Packaging, the client was able to improve the packaging and shipping process for their pool heaters. Together, we were able to pass ISTA testing with no product damage, and do it with no additional shipping costs.

1701 Pearl Street Suite 2

Waukesha, WI 53186

+1 262-203-9522

info@BoldtSmithPackaging.com

Want to keep up with our latest news and alerts? Sign up now and stay in the know.

Copyright © 2024 BoldtSmithPackaging.com