Case study

Furniture

Damage Reduction

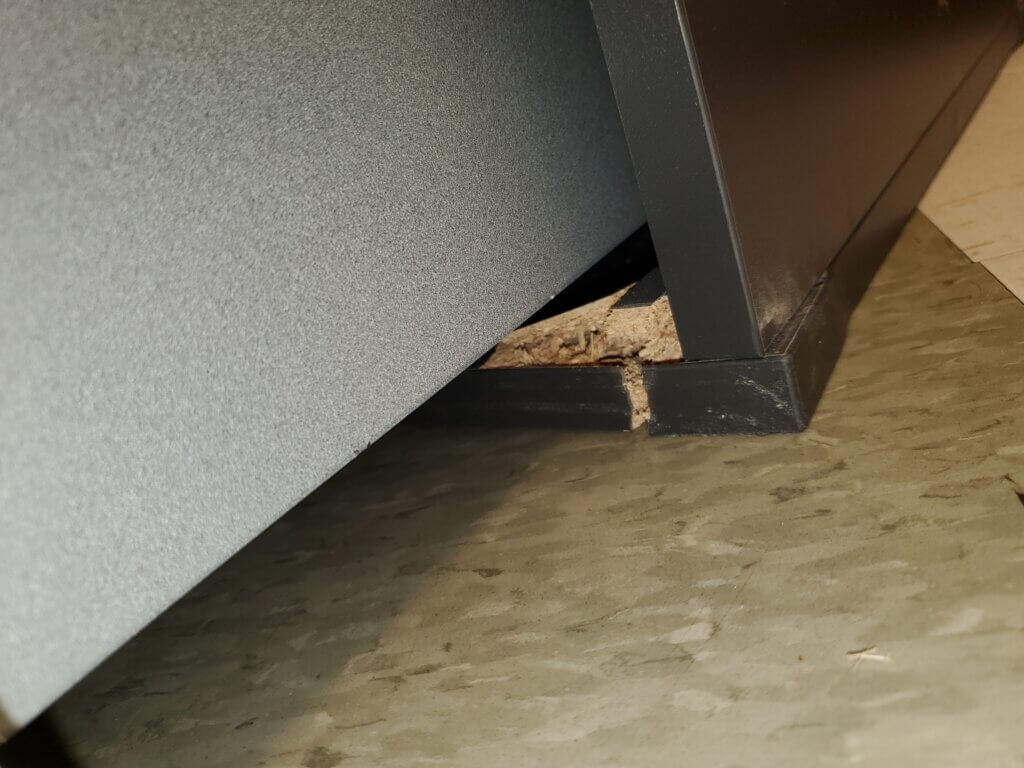

A U.S.-based furniture manufacturer partnered with us to reduce damage during transit. We were challenged to do that without increasing shipping and material costs. Our designs also needed to be optimized for both LTL and FTL supply chains.

Rather than just looking at the damage and suggesting they strengthen the obvious areas of concern in the existing packaging, our “boots on the ground” approach allowed us to isolate where and why the damage was happening.

We looked at the manufacturing site, the point of packaging, and followed the package’s journey to the customer. We also factored the time it took to package the furniture, as well as how easy the packaging was to install.

We proceeded with design options, and tested those options on the same journey. The result was our ability to significantly reduce the rate of damage, with a reduction in material costs and no increase in shipping costs.

10%

Reduction in material costs

.5%

Rate of damage (previously 6%)

$0

Increase in shipping costs

1701 Pearl Street Suite 2

Waukesha, WI 53186

+1 262-203-9522

info@BoldtSmithPackaging.com

Want to keep up with our latest news and alerts? Sign up now and stay in the know.

Copyright © 2024 BoldtSmithPackaging.com