Case Study

Consumer packaged goods

Sustainability

A home craft machinery company faced challenges with oversized packaging. BoldtSmith was tasked with reducing package size by 8 inches while also improving the amount of product that could fit in ocean containers.

We looked to decrease small parcel charges and lower packaging costs while streamlining the assembly process.

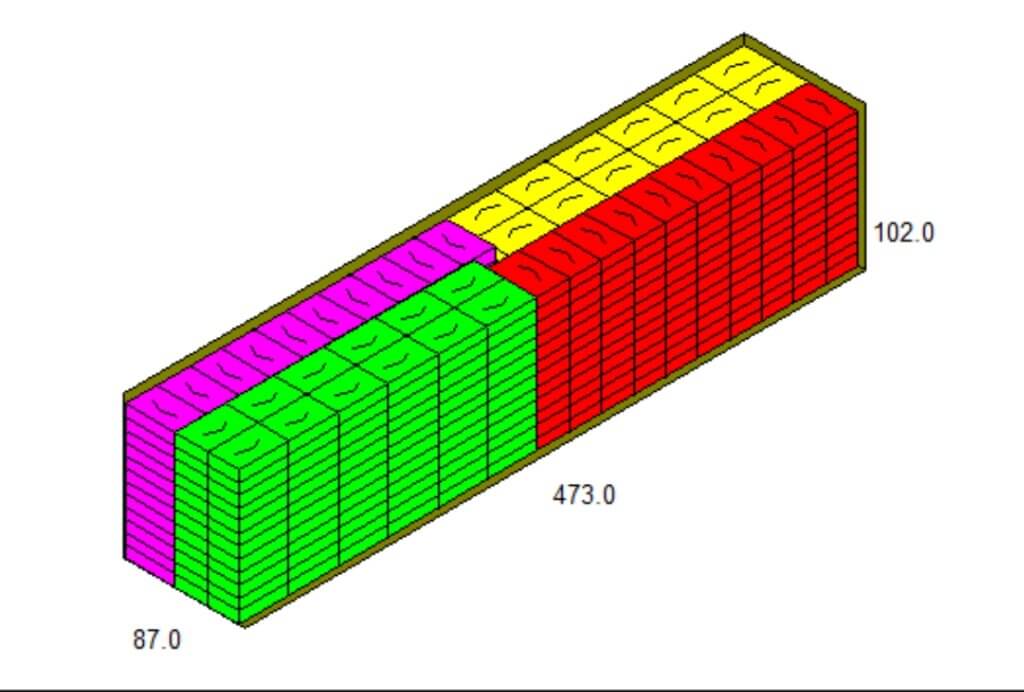

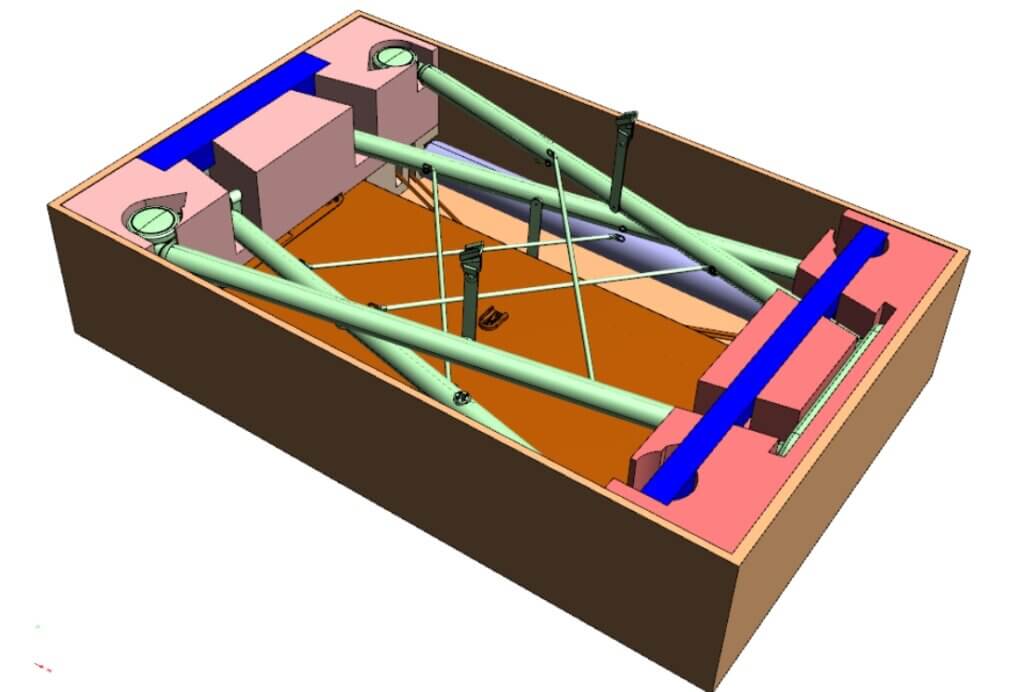

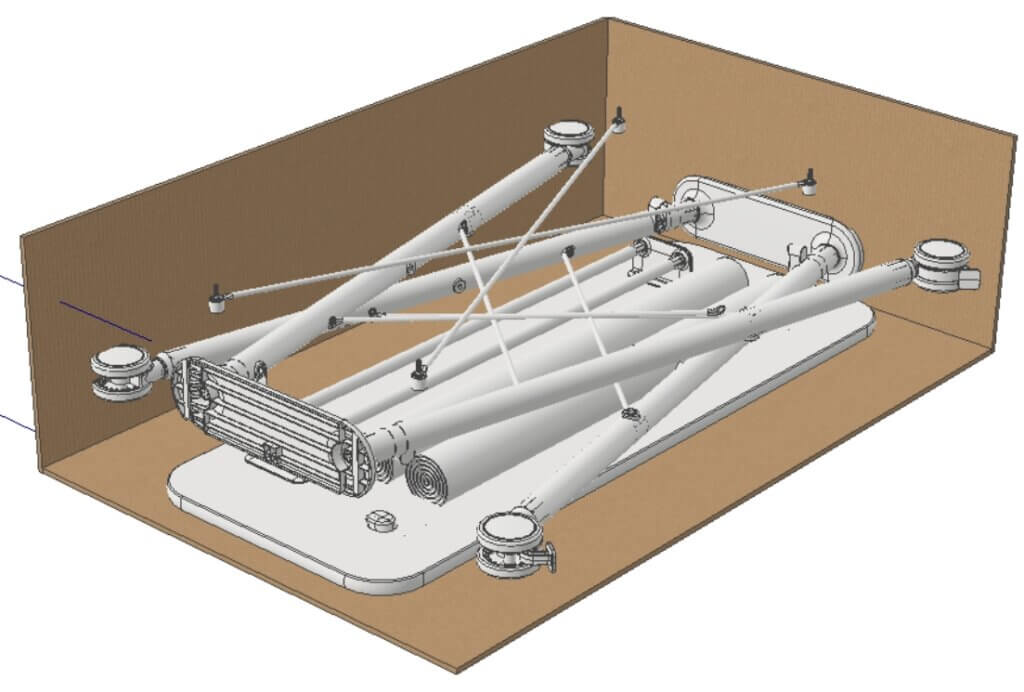

We began by brainstorming multiple packaging concepts and translating these ideas into detailed 3D renderings.

Leveraging our expertise in packaging engineering, we designed an optimized packaging solution that met the company’s requirements. Samples were created and subjected to rigorous testing to ensure durability and effectiveness.

The final prototypes were sent to the product manufacturer overseas for the creation of a first article for BSP inspection.

By reducing package size and eliminating small parcel overcharges, the client achieved cost savings while streamlining their packaging design. The new packaging design required less material while enabling more product to be shipped per ocean container, maximizing efficiency and reducing shipping costs.

BoldtSmith’s innovative approach to packaging engineering delivered tangible results, driving cost savings and operational efficiency.

22.8%

Less corrugated materials used

$800,000

Savings in material costs and labor

36%

More product shipped per ocean container

1701 Pearl Street Suite 2

Waukesha, WI 53186

+1 262-203-9522

info@BoldtSmithPackaging.com

Want to keep up with our latest news and alerts? Sign up now and stay in the know.

Copyright © 2024 BoldtSmithPackaging.com