Case study

Manufacturing & assembly line

Shipping & packaging optimization

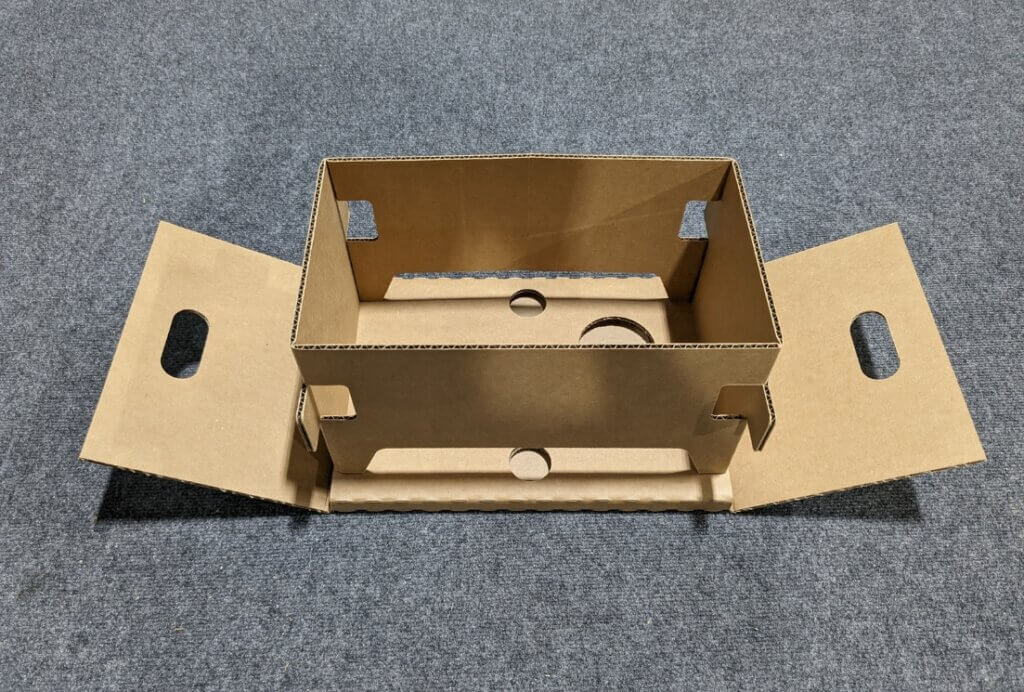

A global technology and engineering company was in need of a solution to optimize the shipping and packaging of gauges which are a critical component to the performance of oil rigs. BoldtSmith provided an engineer to lead this project through the following objectives:

BoldtSmith’s lead engineer worked with the team to ideate potential solutions to the client’s challenge, including 3D renders.

From the possibilities presented, the selected concepts were designed and tested to ensure waste was as minimal as possible, but still maintaining the integrity of the packaging.

A full analysis of the solution and improvements provided showed significant annual savings and opportunity for increased profit.

BoldtSmith’s optimized shipping and packaging solution allowed the client to consolidate various SKU packaging and material cost savings.

$1.3M

Less master carton material

5

Total package sizes across 46 SKUs

1701 Pearl Street Suite 2

Waukesha, WI 53186

+1 262-203-9522

info@BoldtSmithPackaging.com

Want to keep up with our latest news and alerts? Sign up now and stay in the know.

Copyright © 2024 BoldtSmithPackaging.com