Case study

Consumer packaged goods

Cost reduction

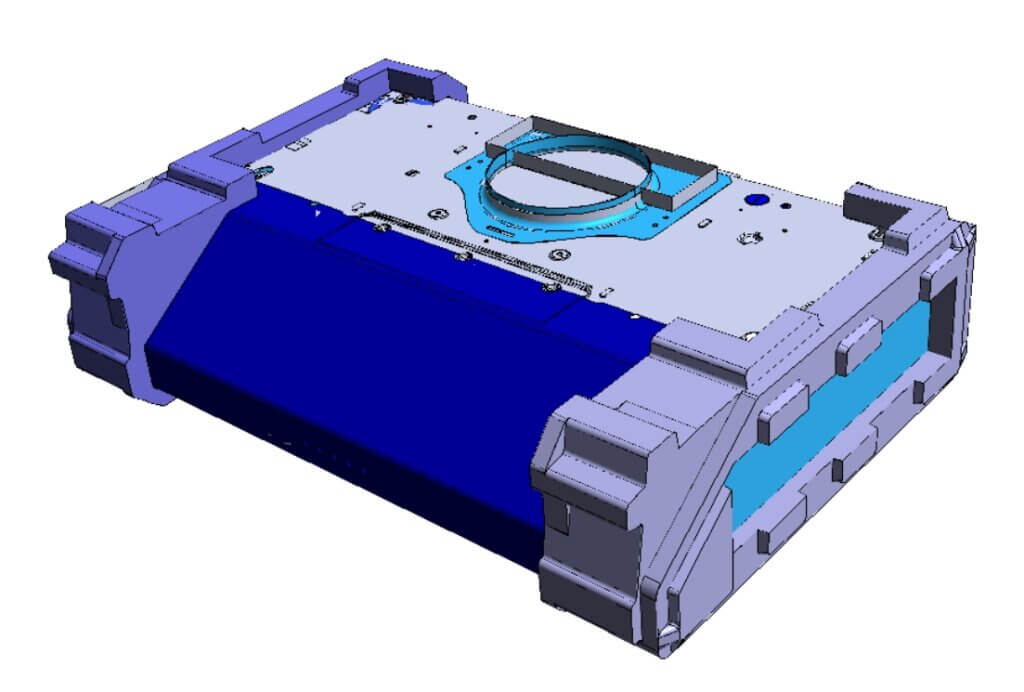

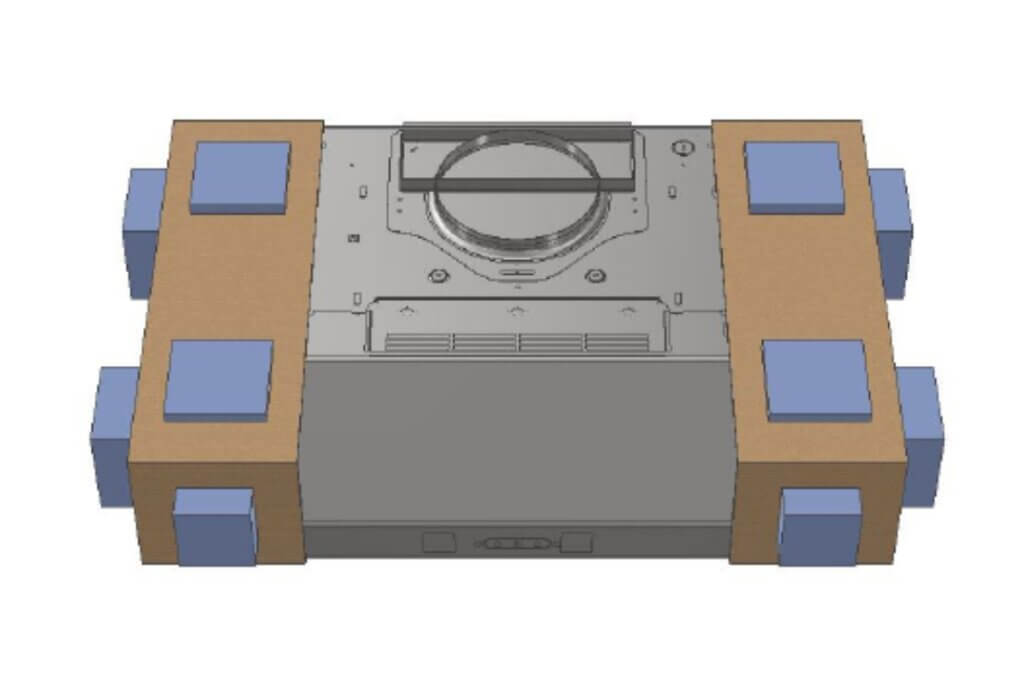

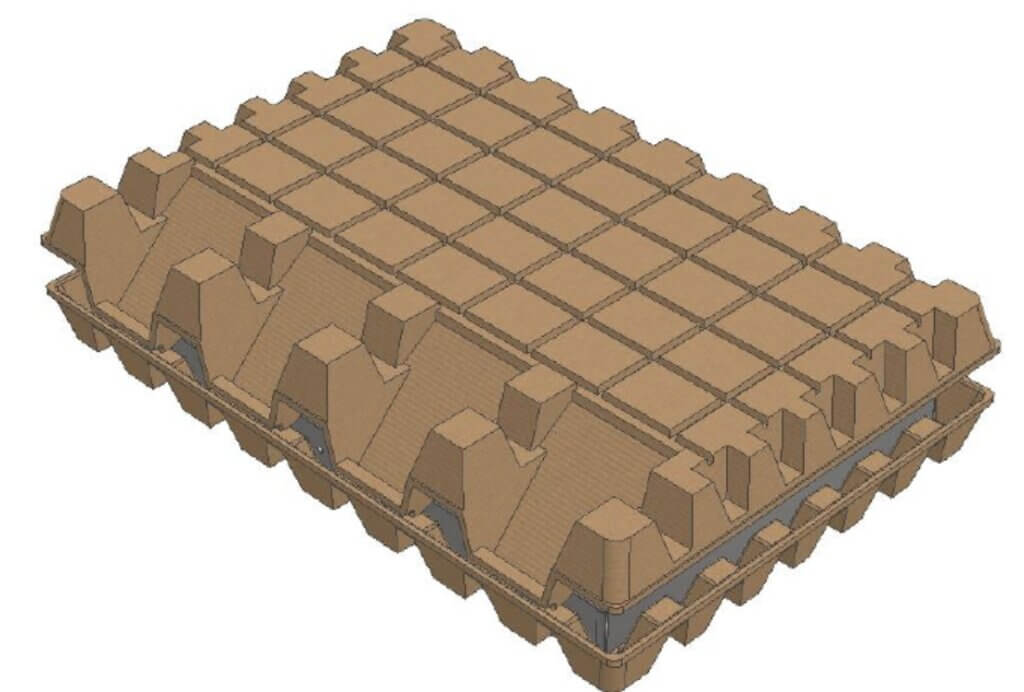

A large manufacturer and provider of fresh air solutions in North America, including range hoods, air purifiers and other air quality equipment, was in need of a partner to help optimize current shipping packaging solutions. They engaged BoldtSmith to help solve the following issues:

BoldtSmith’s engineers worked with the team to review current packaging designs, materials and processes and provide a detailed analysis. They then ideated potential solutions to reduce the client’s costs on packaging materials, freight, labor and product damage

The selected concepts were designed and tested, providing critical data that was used to inform final designs. Then, a full financial analysis of the solution and improvements was conducted to measure and outline significant annual savings and projections for increased profit.

BodtSmith was able to help identify and incorporate effective solutions to the client’s issues that led to significant decrease in product damage while reducing the cost of materials.

76%

Material cost reduction

1701 Pearl Street Suite 2

Waukesha, WI 53186

+1 262-203-9522

info@BoldtSmithPackaging.com

Want to keep up with our latest news and alerts? Sign up now and stay in the know.

Copyright © 2024 BoldtSmithPackaging.com